Mastering Bore Gauge Setting: A Comprehensive Guide to Precision Measurement

Achieving precise internal measurements is critical in numerous engineering and manufacturing applications. The bore gauge, a specialized instrument, is designed for this purpose. However, its accuracy hinges on proper bore gauge setting. This comprehensive guide will walk you through the necessary bore gauge setting steps, ensuring you obtain reliable and repeatable measurements. Whether you’re a seasoned machinist or just starting, understanding these bore gauge setting steps is crucial for quality control and efficient production.

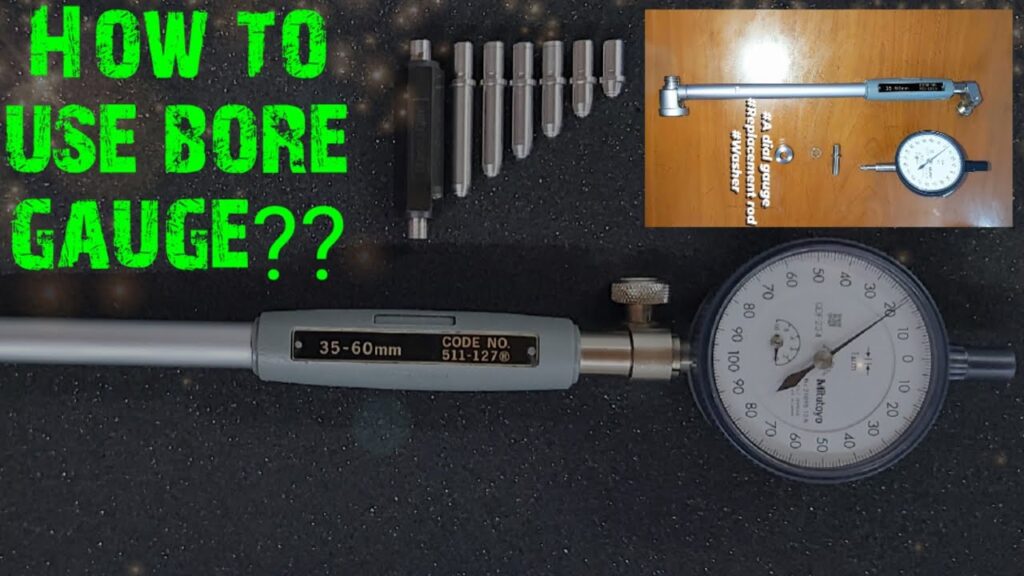

Understanding Bore Gauges

Before diving into the bore gauge setting steps, it’s essential to understand what a bore gauge is and how it functions. A bore gauge is a precision instrument used to measure the internal diameter of holes, cylinders, and other internal features. Unlike calipers or micrometers, bore gauges access hard-to-reach internal dimensions with high accuracy. There are various types, including:

- Dial Bore Gauges: These use a dial indicator to display the measurement difference from a known standard.

- Digital Bore Gauges: These offer a digital readout for enhanced precision and ease of use.

- Telescoping Bore Gauges: These are simpler, less accurate gauges that require transferring the measurement to an external micrometer.

This guide primarily focuses on dial and digital bore gauges, as they are the most commonly used and offer the highest accuracy. Each type of bore gauge requires specific bore gauge setting steps.

Essential Tools and Preparation for Bore Gauge Setting

Proper preparation is key to accurate bore gauge setting. Gather the necessary tools and ensure a clean and stable environment.

Tools Required:

- Bore Gauge: Select the appropriate bore gauge for the size range you need to measure.

- Setting Ring or Micrometer: A setting ring of known diameter or a high-quality external micrometer is essential for setting the bore gauge to a reference standard.

- Gauge Blocks (Optional): For very precise settings, gauge blocks can be used in conjunction with a micrometer to create a highly accurate reference.

- Cleaning Supplies: Clean cloths and a suitable cleaning solution to remove any dirt or debris from the bore gauge, setting ring, or micrometer.

- Work Bench: A stable and clean workbench to perform the bore gauge setting steps.

Preparation Steps:

- Cleanliness: Thoroughly clean the bore gauge, setting ring (or micrometer anvils), and the workpiece. Contaminants can significantly affect measurement accuracy.

- Acclimation: Allow the bore gauge, setting ring, and workpiece to acclimate to the same temperature. Temperature differences can cause expansion or contraction, leading to errors.

- Inspection: Inspect the bore gauge for any damage or wear. Ensure the dial indicator moves smoothly and the contact points are in good condition.

Detailed Bore Gauge Setting Steps

Now, let’s delve into the detailed bore gauge setting steps. The specific procedure may vary slightly depending on the type of bore gauge and the reference standard used, but the general principles remain the same.

Using a Setting Ring:

- Select the Appropriate Setting Ring: Choose a setting ring with a diameter close to the size of the bore you intend to measure. The setting ring provides a known reference point.

- Insert the Bore Gauge into the Setting Ring: Carefully insert the bore gauge into the setting ring. Ensure the contact points of the gauge are making proper contact with the inner surface of the ring.

- Adjust the Bore Gauge: Adjust the bore gauge until the dial indicator reads zero (or the digital display shows the setting ring’s diameter). Most bore gauges have an adjustment mechanism, such as a knurled knob or a fine-adjustment screw.

- Rock the Gauge: Gently rock the bore gauge back and forth within the setting ring. Observe the dial indicator or digital display. The lowest reading indicates the true diameter.

- Lock the Setting: Once the bore gauge is set to the setting ring’s diameter, lock the setting mechanism to prevent accidental adjustments.

- Verification: Remove the bore gauge from the setting ring and re-insert it to verify the setting. The reading should be consistent.

Using a Micrometer:

- Set the Micrometer: Set the external micrometer to the desired diameter. Use gauge blocks for higher accuracy if needed.

- Position the Bore Gauge: Position the bore gauge between the anvils of the micrometer. Ensure the contact points of the gauge are aligned with the micrometer anvils.

- Adjust the Bore Gauge: Adjust the bore gauge until the dial indicator reads zero (or the digital display matches the micrometer setting).

- Rock the Gauge: Gently rock the bore gauge back and forth between the micrometer anvils. The lowest reading indicates the true diameter.

- Lock the Setting: Once the bore gauge is set to the micrometer setting, lock the setting mechanism.

- Verification: Remove the bore gauge from the micrometer and re-insert it to verify the setting. The reading should be consistent.

Tips for Accurate Bore Gauge Measurement

Following these tips will help you achieve the most accurate measurements with your bore gauge. These tips are vital after completing the bore gauge setting steps.

- Proper Technique: Always rock the bore gauge to find the true diameter. This ensures the contact points are aligned with the bore.

- Consistent Pressure: Apply consistent pressure when taking measurements. Excessive or insufficient pressure can lead to errors.

- Multiple Measurements: Take multiple measurements at different points within the bore to check for variations in diameter (out-of-roundness, taper).

- Regular Calibration: Calibrate your bore gauge regularly to ensure it maintains its accuracy. The frequency of calibration depends on usage and the required level of precision.

- Proper Storage: Store your bore gauge in a clean and dry environment to prevent damage and corrosion.

Common Mistakes to Avoid

Avoiding these common mistakes can significantly improve the accuracy of your bore gauge measurements. These mistakes often occur even after careful completion of the bore gauge setting steps.

- Ignoring Cleanliness: Failing to clean the bore gauge, setting ring, or workpiece can introduce errors.

- Incorrect Setting: Improperly setting the bore gauge to the reference standard is a major source of error. Double-check the setting before taking measurements.

- Using a Damaged Gauge: Using a bore gauge with damaged contact points or a malfunctioning dial indicator will compromise accuracy.

- Temperature Variations: Neglecting temperature variations can lead to inaccurate measurements. Allow the bore gauge, setting ring, and workpiece to acclimate to the same temperature.

- Applying Excessive Force: Applying too much force when inserting the bore gauge into the bore can damage the instrument and affect the measurement.

Advanced Techniques and Considerations

For more demanding applications, consider these advanced techniques and considerations.

Using Gauge Blocks for High Accuracy:

Gauge blocks provide the highest level of accuracy when setting a bore gauge. They can be used in conjunction with a micrometer to create a highly precise reference standard. This is particularly useful when measuring bores with very tight tolerances.

Measuring Deep Bores:

When measuring deep bores, use extension rods to reach the desired depth. Ensure the extension rods are properly aligned and securely attached to the bore gauge to prevent errors.

Dealing with Irregular Bores:

If the bore is not perfectly round or has irregularities, take multiple measurements at different angles and depths to map the bore’s profile. This will provide a more complete understanding of the bore’s dimensions.

Conclusion

Mastering bore gauge setting steps is essential for achieving accurate and reliable internal measurements. By following the steps outlined in this guide, paying attention to detail, and avoiding common mistakes, you can ensure your bore gauge measurements are precise and consistent. Regular calibration and proper maintenance will further enhance the performance and longevity of your bore gauge. Remember, a properly set and maintained bore gauge is a valuable tool for any machinist or engineer striving for precision in their work. Consistent adherence to these bore gauge setting steps will lead to improved quality control and reduced errors in manufacturing processes. [See also: Understanding Micrometer Calibration] [See also: Choosing the Right Measuring Instrument] [See also: Precision Measurement Techniques]